TANK MEASUREMENT & INTEGRITY

|

Tank Measurement & Integrity was acquired by Beacon Energy Services to offer additional services to our clients. Led by Steve Furnish, Tank Measurement & Integrity specializes in:

All calculations are done by professionals with working knowledge of American Petroleum Institute (API), Institute of Petroleum (IP), and International Organization of Standardization (ISO) standards. Steve Furnish is an industry veteran with 25 years of experience. Beacon Energy Services, partnered with Tank Measurement & Integrity, strives to be your first choice in tank calibration, analysis, and 3D model production. We are committed to providing professional services to facilities and terminals across the country with fast, accurate calibration and analysis of bulk storage tanks. |

Other Services

|

Liquid Storage Tank Calibration

Liquid storage tank calibration, or liquid calibration, is the most accurate method of calibration. It excels when used on irregular or difficult to measure bulk liquid storage such as tanker trucks, uneven bottoms of storage tanks, ships and barges, spherical tanks, rail car tanks, or small horizontal storage tanks. For any bulk liquid container, it is critical to accurately track the volume of liquid stored for efficient facility management and tank operation. Inaccurate or missing data can lead to errors such as tank rupture or floating roof collision. These errors are detrimental in not only repair costs, but production loss and environmental impact. If you need to know the amount of liquid transferred into or out of a storage tank, you will need professional storage tank calibration.

Liquid calibration is an involved, time-consuming process. Liquid (typically water) is metered into the tank at intervals, then the level of the liquid is measured. Either the full capacity or part of the capacity of a tank may be calibrated. It is also possible to verify the operation and weight of floating roofs during calibration. Our meters are verified against a state-certified volumetric prover to ensure their accuracy, and all calculations are done by professionals with working knowledge of API, IP, and ISO standards.

Liquid calibration is an involved, time-consuming process. Liquid (typically water) is metered into the tank at intervals, then the level of the liquid is measured. Either the full capacity or part of the capacity of a tank may be calibrated. It is also possible to verify the operation and weight of floating roofs during calibration. Our meters are verified against a state-certified volumetric prover to ensure their accuracy, and all calculations are done by professionals with working knowledge of API, IP, and ISO standards.

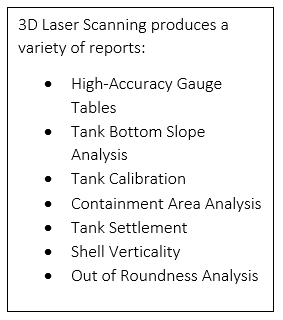

3D Laser Scanning3D Laser Scanning is a fast, cost-effective method of tank strapping. It provides millions of data points for analysis, reporting, and creation of 3D models. The 3D model can be used to visualize future changes while the tank is still in service. Examples of future changes might be adding or modifying platforms, heat coils, or making changes to the floating roof. These advantages give 3D scanning an edge over other surveying methods.

Manual Strapping has been a popular tank calibration method for many decades. To manually strap a tank, a certified tape is wrapped around the tank. However, it is unable to match the speed an accuracy of 3D scanning and cannot generate the variety of reports for your records. Electro-Optical Distance Ranging (EODR) is another basic surveying technique. In additional to determining layouts by triangulation, EODR can also measure the distance to the point being surveyed. While EODR was cutting edge in the 90s, replacing the Optical Reference Line method of the 80s, it has been eclipsed by 3D scanning with its capability of measuring millions of points. |

Secondary Containment Survey

Secondary Containment is an impermeable barrier that prevents leaks from the storage tank from reaching outside the containment area. It should be able to contain a spill or leak in the event of a failure. For environmental compliance and business risk management, secondary containment surveys ensure that the stored product will not overflow in the event of tank failure. Using the 3D model produced from the 3D laser scans, we can compute the containment capacity and model spill scenarios. Our secondary containment report details the adequacy of containment including tank volume and spill point to ensure regulatory compliance.

If the survey is extended beyond the secondary containment, we can also use the 3D scan to examine the route any spills may take in the event of an incident. Adequate containment systems are critical to prevent harmful products from escaping into the ground or streams and must meet state and federal capacity regulations.

If the survey is extended beyond the secondary containment, we can also use the 3D scan to examine the route any spills may take in the event of an incident. Adequate containment systems are critical to prevent harmful products from escaping into the ground or streams and must meet state and federal capacity regulations.